Recommended Methods (in order):

Vapour Blasting

Dry Ice Blasting

Soda Blasting

OPTION #1: VAPOUR BLASTING

Main Advantages:

– Fast

– Minimal water run-off

– ZERO damage to surface

Disadvantages:

– Loud

– Not safe around close pedestrian traffic

– Not great for removing tags from painted surfaces

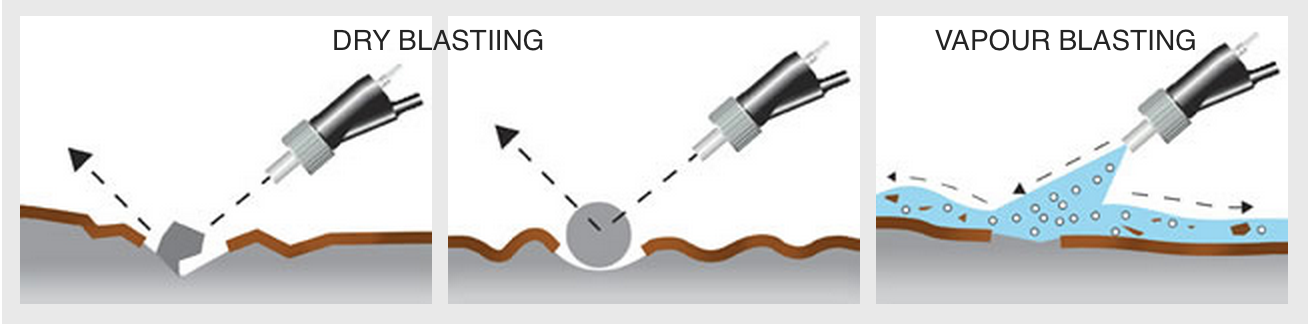

Vapour Blasting, also known as “wet abrasive”, or “dustless blasting”, is an abrasive blasting technique that, in a way, can be compared to “sandblasting” in that the active propellant is abrasive blast media ie. sand, garnet, crushed glass, aluminum oxide, baking soda. The difference however, is that the Vapour Blasting system mixes the media with water. The addition of water buffers and lubricates the particles providing a cushion that can protect both the media and the surface from excess damage. This has the dual advantage of increasing the effectiveness of the media by lowering media breakdown, and by preventing impregnation of foreign materials into the surface.

ADVANTAGES OVER CONVENTIONAL BLASTING:

– environmental excellence

– minimal debris containment required

– 1/10th the media consumption

– 1L per minute water consumption

– Wide array of 100% inert blast media choices

– 90% dust-free

– no media embedment in substrate

– consistent finish

– no static build-up

– extremely clean surface left behind

– safe on plastic or steel

– add hot water and soap for degreasing

– no heat production

OPTION #2: DRY ICE BLASTING

Main Advantages:

– ZERO secondary waste stream

– ZERO water run-off

– ZERO damage to surface

– Eco-superiority around environmentally sensitive areas

Disadvantages:

– Loud

– Not safe around close pedestrian traffic

– Not great for removing tags from painted surfaces

– equipment must be within 80′ of work area

Dry Ice Blasting is a process in which hard pieces of frozen CO2 pellets are shot at a surface with compressed air. The extreme cold (-79°C -109°F) causes the contaminant to become brittle by causing a thermal differential between the layer of debris and the substrate. The cold shrinks the debris causing it to contract, and weaken the bond with the substrate, which when combined with the micro- explosions created by the sublimation process (800x/ms), the contaminant explodes from the surface without altering or abrading the profile of the underlining substrate. CO2 pellets can strip paints and remove grease and oil. The pellets themselves can be fragmented and can propelled at various speeds to increase cleaning rates or reduce surface damage.

OPTION #3: SODA BLASTING

Main Advantages:

– Can be used with or without water

– ZERO damage to surface

– Can be used around some environmentally sensitive areas

Disadvantages:

– Loud

– Extensive debris field

– Not safe around vegetation

– Not safe around close pedestrian traffic

– Not great for removing tags from painted surfaces

Soda Blasting is a form of media blasting in which sodium bicarbonate (baking soda) is used to gently clean and restore surfaces, and because the media is so soft it is considered to be a non-destructive media blasting method. Soda Blasting, although widely accepted as a solid alternative to “sandblasting” when substrate profiles must be left unaltered, finds it’s most effective uses in cleaning & restoration applications where odour absorption is required, or when used in food-safe environments. Since the adaption of Vapour Blasting technology, EcoJet employs the use of Soda Blasting quite sparingly especially when debris field containment is required or when working near vegetation that can be harmed by the pH causticity of sodium bicarbonate.